Any links to other websites / pages given by TRAD UK are provided as a convenience and for informational purposes only; they do not constitute any endorsement or approval by TRAD UK of any of the content, products, services or opinions of the corporation, organisation or individual. TRAD UK bears no responsibility for the accuracy, legality or content of the external site or for that of subsequent links. Contact the external site for answers to questions regarding its content.

Knowledge Inspired Mental Health & Wellbeing Safety, Health & Environment Visual Standards Diversity & Inclusion

At TRAD we consider our people to be our greatest asset. Our Values are centred on our employees. As a company we strive to be open, innovative and dynamic, viewing ourselves as a team that engages with clients, suppliers and employees under a common sense banner that encourages new ideas, development of people, and quality and uniformity of service.

The objective is to create better communication with all employees, helping them to understand all aspects of Health & Safety which affect and are relevant to their role, while improving on the overall quality of their working conditions and giving them full knowledge of the Company Standards and their personal responsibilities.

It is equally important to provide the employees with a platform whereby they are being represented, allowing them a confidential place to air their views, talk about any problems and issues they are encountering, whilst giving them the opportunity to provide the TRAD Group with positive ideas which may assist in achieving its aims and objectives.

Our vision is to drive innovation, quality and best practice so we can continue to produce even safer working environments for our employees, our clients’ operatives and the general public, whilst establishing a reputation of being at the forefront and leading edge of improving UK safe access and scaffolding industries.

Always ensure all who erect, adapt and dismantle the scaffold are trained and competent to do so.

Always ensure all risk assessments and method statements have been carried out, then communicated to those concerned, and understood.

Always ensure that there is adequate storage for the materials.

Always ensure that there is clear access to the work area and that the ground is level and suitable for the scaffold.

Always work to the current edition of the NASC guidance note SG4 – “Preventing Falls in Scaffolding Operations”.

Always ensure that there are adequate tying points.

Always ensure loads are evenly distributed.

Always ensure scaffold inspections are carried out and recorded as per current legal requirements.

Always ensure that all defects are notified to the site management.

Never let untrained persons erect, modify or dismantle the scaffold.

Never remove guardrails, toe boards or brick guards.

Never remove ties without prior approval.

Never create gaps in platforms by removing decks or boards.

Never remove restrictions or warning signs from the scaffold structure.

Never undermine the scaffold by digging trenches underneath or near the base.

Never add sheeting or netting without prior approval.

Never use damaged materials.

Never allow unqualified / unapproved personnel to repair damaged equipment.

Never load directly on to the access scaffold’s working platform (always use a loading tower).

The current edition of the Work at Height Regulations places a duty on employers to protect individuals from harm. Scaffolding inevitably carries a risk of falling from height and consequently, it is of paramount importance that all activities are assessed for risk, planned and a safe system of work is adopted during any scaffold activity. It is therefore strongly recommended that the procedures outlined in the NASC’s guidance note SG4 – “Preventing Falls in Scaffolding Operations” are followed. SG4 describes several safe methods of work, including the use of collective fall protection systems such as an advanced guardrail or scaffolder’s steps.

To ensure the safety of scaffold erectors, it is important that fall protection equipment is only attached to those components which are capable of withstanding any likely imposed loads. Where system scaffolds are involved, please refer to the particular user guide for the system which is being used for the relevant connection points.

While the current Work at Height Regulations requires that work at height be carried out safely, they also require that contingency plans be made for any eventuality. This extends to making plans to rescue personnel suspended by fall arrest equipment. Personnel should be fully trained to use all relevant rescue equipment for the event of a suspended casualty.

Details relating to rescue and what should be considered can be found in the latest editions of the NASC guidance notes SG4 & SG19 (SG19 – “A Guide to Formulating a Rescue Plan”).

Only trained and authorised scaffold operatives should carry out the erection, dismantling or modification of any scaffold structure. Consideration must also always be given to those that may be affected by the works being carried out. To ensure that the highest standards of safety performance are maintained, attention should be given to the following:

The following basic rules should be adhered to when manually handling scaffolding equipment:

Always use the correct kinetic handling technique:

Details relating to manual handling and what should be considered can also be found in the latest edition of the NASC guidance note SG6 – “Manual Handling in the Scaffolding Industry”.

Remember – safety is no accident. Don’t risk it – if in doubt ask!

Ensure that you have segregated your workplace from members of the public and other site operatives.

Do you know your safe system of work and do you have the right equipment?

Have you and are you wearing the correct PPE for the task?

Avoid injury from slips and trips by keeping your work area tidy.

Is the equipment used and / or erected to a high standard and the work carried out with pride?

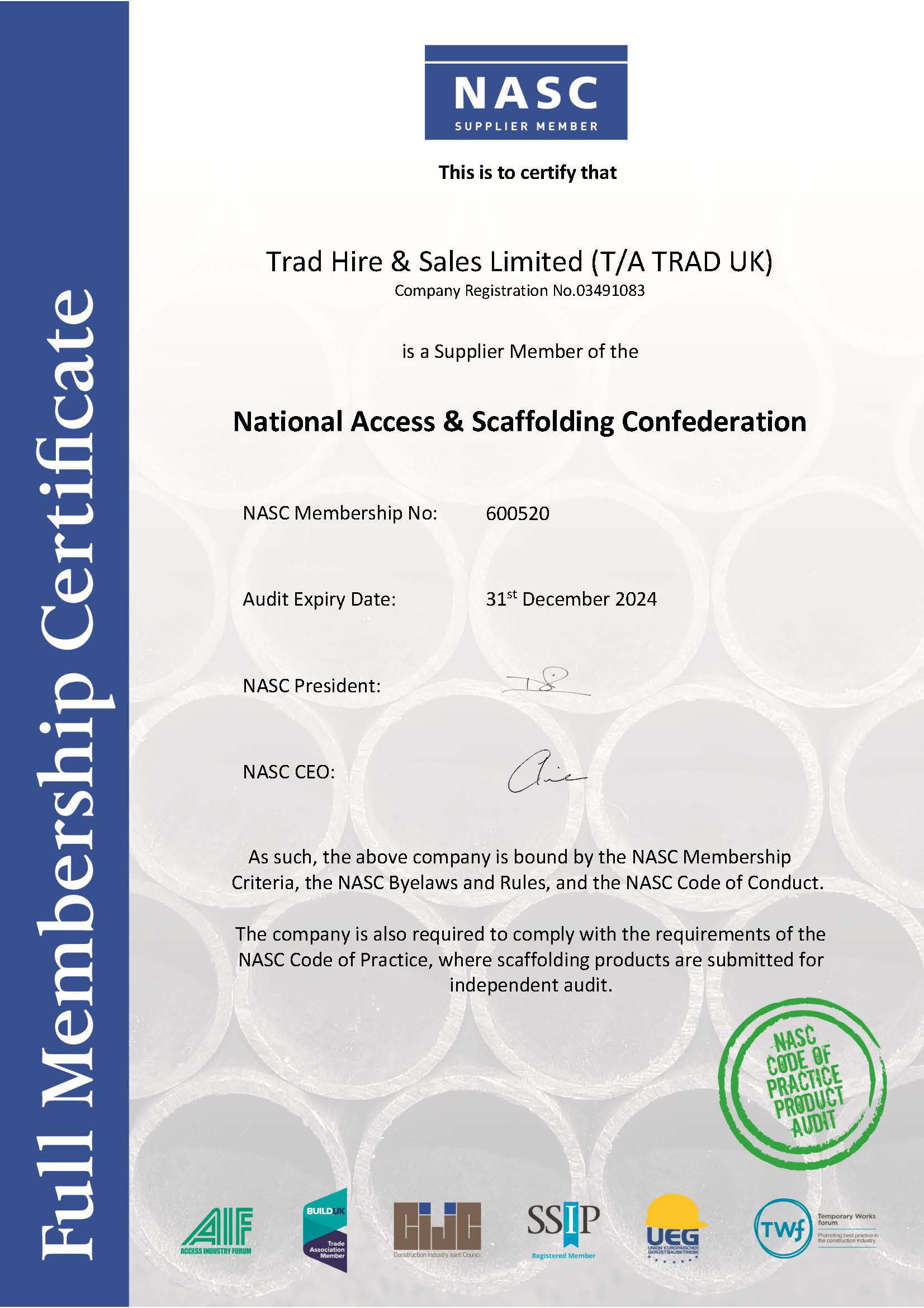

The NASC is recognised as the national trade body for access and scaffolding in the UK, producing a wide range of industry guidance for scaffolding contractors, their operatives and their clients. Members of the NASC are strictly regulated to ensure a continuous high standard of scaffolding practice.

The Scaffolding Association is the largest trade organisation in the UK scaffolding and access sector, campaigning to raise standards of safety, quality and workforce skills.

Leading the Construction industry to change for the better in the discipline of temporary works…

The aim of Temporary Works forum (TWf) is to encourage open discussion of any matter related to temporary works, for the good of the industry overall. The Forum is open to anyone, individual or corporate, working within the industry and sharing this intent.

Mission

To be an advocate and recognized authority on temporary works and construction method design, working to raise standards and awareness across the construction sector.

Royal Society for the Prevention of Accidents – actively involved in the promotion of safety and the prevention of accidents in all areas, demonstrating our commitment to safety and providing us with operational guidelines.

ISO 9001 is the internationally recognized Quality Management System (QMS) standard that can benefit any size of organization and is designed to be a powerful business improvement tool.

TRAD UK have been audited by BSi and are accredited to ISO 9001:2015.

POLICY STATEMENT

TRAD UK are established market leaders in the scaffolding hire and sales / fall prevention solutions market sector. The company has developed plans for continued organic growth for increasing market share and a commitment to continually improve the service we provide to our loyal customers. This will be achieved by our fully trained and professional teams supplying the highest quality products and delivering the highest quality service.

TRAD UK recognises the importance of the quality of our products, operations and service to achieving our company quality objectives. Our quality objectives have been planned and established with quantified, measurable goals that drive improvement and focus on maintaining and improving customer satisfaction. TRAD UK’s Senior Management have provided the resources and funds necessary to implement this policy and to achieve its quality objectives. It is, therefore, our policy to operate a Quality Management System that fully complies with the requirements of ISO9001:2015. This policy will be reviewed regularly to ensure its relevance to the strategic direction of the organisation.

The TRAD UK Top Management Team have shown commitment to satisfying all applicable requirements and compliance with customer, regulatory and statutory requirements, with industry codes of practice and relevant product standards (BS and EN). We also commit to continually improve our Quality Management System for sustained customer satisfaction and to continually meet the requirements of all interested parties.

This policy will be communicated to all employees and organisations working for and on behalf of TRAD UK and will be made available to all interested parties upon request.

The Fleet Operator Recognition Scheme (FORS) is a voluntary accreditation scheme for fleet operators which aims to raise the level of quality within fleet operations, and to demonstrate which operators are achieving exemplary levels of best practice in safety, efficiency, and environmental protection.

CHAS is established as the market leader for health and safety pre-qualification in the UK. It is available to suppliers (those who provide goods and services) and to organisations (buyers) looking for suitably competent suppliers.

Constructionline is the UK’s largest Government-owned register of contractors and consultants for the construction industry. Constructionline standards are high, all suppliers are pre-qualified to the official Government pre-qualified standard.

BuildingConfidence is recognised as the standard for supplier excellence within the industry. Major contractors are using the service to evaluate their supply chains, drive up performance and forge longer lasting relationships with key suppliers.

BM TRADA membership and subsequent annual Scaffold Board grading accreditation allows TRAD to inspect the quality of their scaffold boards both new and in service. This ensures that the quality of their scaffold boards are always measured and comply with the current BS2482 – 2009 standard.

Alcumus is trusted by the world’s most respected organisations to help them create better, more sustainable workplaces.

The Alcumus SafeContractor scheme is a market-leading health & safety accreditation system, helping contractors and organisations become healthier and safer, and gaining SafeContractor status demonstrates an organisation’s compliance with increasingly stringent legislation.

This SafeContractor certificate has been awarded for the following services…

Work Categories:

Fall Protection Safety Systems: Fall Protection Safety Systems

Supplier & Service Provider: Access Equipment Hire Provider

Industry Roles:

Construction Contractor, Supplier

Category Related Activities:

Ladders / Step Ladders, Selection & Control of Subcontractors, Working at Height