Scaffolding plays a vital role on every construction site. From housing builds to large infrastructure projects, safe access to height is essential. But working at height comes with risk. That is why scaffolding safety is one of the most important parts of site planning and ongoing worksite management.

This guide explores the risks, safety tips, and how Trad UK helps raise safety standards with trusted scaffolding equipment and protocols.

Falls from height remain one of the most common causes of death and serious injury in the construction industry (HSE). Every scaffold must be erected, used and maintained with safety in mind. Following proper guidance reduces accident risks and helps avoid legal penalties or site shutdowns.

Understanding the key risks helps avoid them. The main dangers include:

Quality equipment is the foundation of a safe scaffold. Key safety supplies include:

Trad UK supplies certified materials that meet or exceed UK industry standards. Our scaffolding boards, safety netting, and ring system gear are built to last.

Here are practical ways to reduce risk from day one:

All scaffolding must be inspected:

Inspection records should be kept on site. Using scaffold tagging systems makes this simple and visible.

(Source: Simian )

Focusing on safety is more than just good practice. It brings real benefits:

At Trad UK, our scaffolding solutions are designed with safety at their core:

All our systems are aligned with HSE and NASC best practices to help you meet legal duties and safeguard lives.

What are the main causes of scaffolding accidents?

Falls from height, unstable scaffolds, and lack of proper inspection are the most common causes.

What safety equipment should be used on scaffolding?

Guardrails, netting, toe boards, PPE, and secure access ladders are essential for safe scaffolding.

How does Trad UK improve scaffolding safety?

Trad UK provides tested systems like Plettac Metrix, safe loading systems, and lighter materials to reduce risk across all stages of scaffolding work.

What are the legal requirements for scaffolding in the UK?

Scaffolding must be erected and inspected by a competent person. It must meet the standards of the Work at Height Regulations 2005 and follow safe design, load, and fall prevention rules (HSE).

How often should scaffolding be inspected?

Scaffolds must be inspected before first use, after any alterations or bad weather, and every 7 days while in use (HSE).

Do I need guardrails and toe boards?

Yes. Platforms should have guardrails at a minimum of 950mm high and toe boards to prevent items falling from height (HSE).

What makes a scaffold safe to use?

Stability, correct design, secure access, proper use of fittings, and regular inspections. Using trusted systems like Plettac Metrix helps meet these standards.

The NASC is recognised as the national trade body for access and scaffolding in the UK, producing a wide range of industry guidance for scaffolding contractors, their operatives and their clients. Members of the NASC are strictly regulated to ensure a continuous high standard of scaffolding practice.

The Scaffolding Association is the largest trade organisation in the UK scaffolding and access sector, campaigning to raise standards of safety, quality and workforce skills.

Royal Society for the Prevention of Accidents – actively involved in the promotion of safety and the prevention of accidents in all areas, demonstrating our commitment to safety and providing us with operational guidelines.

ISO 9001 is the internationally recognized Quality Management System (QMS) standard that can benefit any size of organization and is designed to be a powerful business improvement tool.

TRAD UK have been audited by BSi and are accredited to ISO 9001:2015.

POLICY STATEMENT

TRAD UK are established market leaders in the scaffolding hire and sales / fall prevention solutions market sector. The company has developed plans for continued organic growth for increasing market share and a commitment to continually improve the service we provide to our loyal customers. This will be achieved by our fully trained and professional teams supplying the highest quality products and delivering the highest quality service.

TRAD UK recognises the importance of the quality of our products, operations and service to achieving our company quality objectives. Our quality objectives have been planned and established with quantified, measurable goals that drive improvement and focus on maintaining and improving customer satisfaction. TRAD UK’s Senior Management have provided the resources and funds necessary to implement this policy and to achieve its quality objectives. It is, therefore, our policy to operate a Quality Management System that fully complies with the requirements of ISO9001:2015. This policy will be reviewed regularly to ensure its relevance to the strategic direction of the organisation.

The TRAD UK Top Management Team have shown commitment to satisfying all applicable requirements and compliance with customer, regulatory and statutory requirements, with industry codes of practice and relevant product standards (BS and EN). We also commit to continually improve our Quality Management System for sustained customer satisfaction and to continually meet the requirements of all interested parties.

This policy will be communicated to all employees and organisations working for and on behalf of TRAD UK and will be made available to all interested parties upon request.

What is ISO 37001?

ISO 37001 is a standard dedicated to establishing, implementing, maintaining, and improving an anti-bribery management system. This standard offers requirements and guidance for setting up systems designed to help organizations prevent, detect, and respond to bribery, as well as comply with anti-bribery laws and voluntary commitments applicable to their activities. It covers various forms of bribery (direct and indirect) within public, private, and not-for-profit sectors.

Why is ISO 37001 important?

Bribery is a pervasive issue that undermines societal, economic, and political structures, leading to injustice, distorted competition, and increased operational costs among other severe implications. ISO 37001 is critical as it provides organizations with a systematic approach to combat bribery. This approach is not only about legal compliance but also about fostering a culture of integrity, transparency, and trust within organizations. By implementing an anti-bribery management system, organizations can mitigate risks and damage associated with bribery, enhance their reputation, and ensure stable and fair market operations.

The Fleet Operator Recognition Scheme (FORS) is a voluntary accreditation scheme for fleet operators which aims to raise the level of quality within fleet operations, and to demonstrate which operators are achieving exemplary levels of best practice in safety, efficiency, and environmental protection.

CHAS is established as the market leader for health and safety pre-qualification in the UK. It is available to suppliers (those who provide goods and services) and to organisations (buyers) looking for suitably competent suppliers.

Constructionline is the UK’s largest Government-owned register of contractors and consultants for the construction industry. Constructionline standards are high, all suppliers are pre-qualified to the official Government pre-qualified standard.

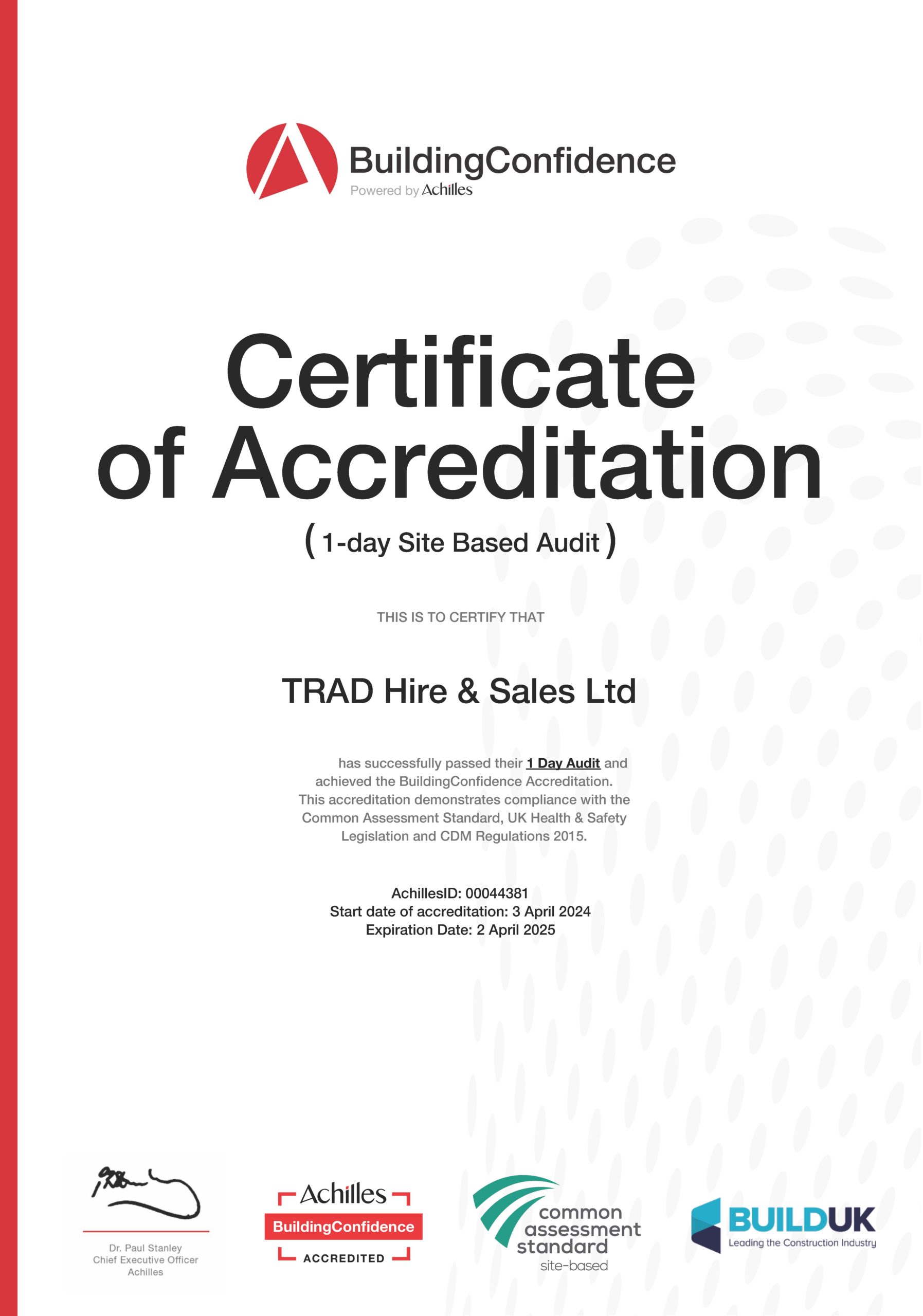

BuildingConfidence is recognised as the standard for supplier excellence within the industry. Major contractors are using the service to evaluate their supply chains, drive up performance and forge longer lasting relationships with key suppliers.

BM TRADA membership and subsequent annual Scaffold Board grading accreditation allows TRAD to inspect the quality of their scaffold boards both new and in service. This ensures that the quality of their scaffold boards are always measured and comply with the current BS2482 – 2009 standard.

Alcumus is trusted by the world’s most respected organisations to help them create better, more sustainable workplaces.

The Alcumus SafeContractor scheme is a market-leading health & safety accreditation system, helping contractors and organisations become healthier and safer, and gaining SafeContractor status demonstrates an organisation’s compliance with increasingly stringent legislation.

This SafeContractor certificate has been awarded for the following services…

Work Categories:

Fall Protection Safety Systems: Fall Protection Safety Systems

Supplier & Service Provider: Access Equipment Hire Provider

Industry Roles:

Construction Contractor, Supplier

Category Related Activities:

Ladders / Step Ladders, Selection & Control of Subcontractors, Working at Height